Description

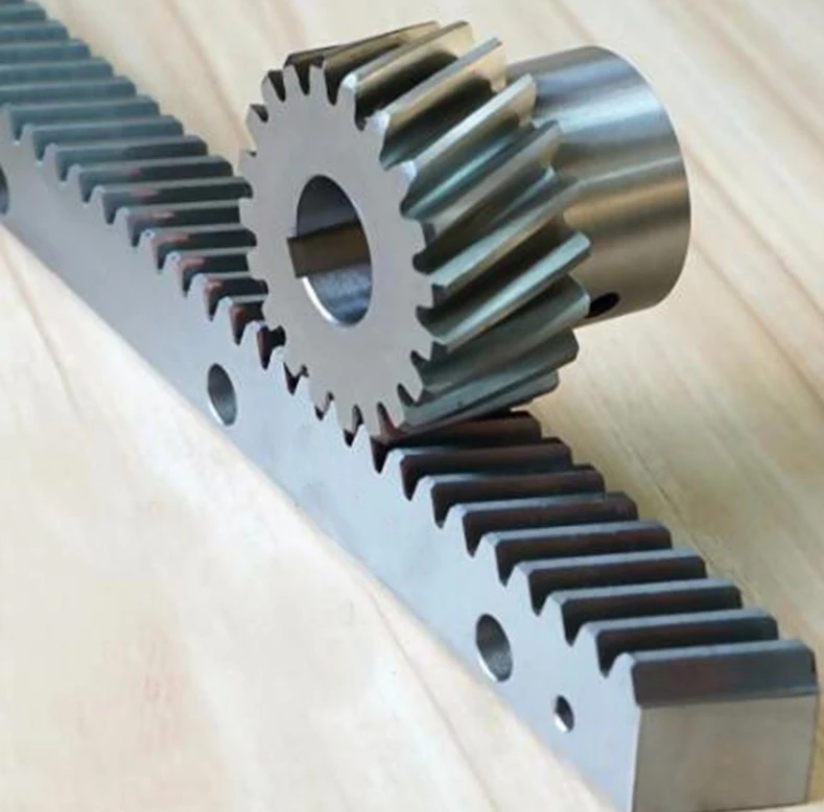

high precision rack pinion gear custom machining CNC steel gear racks

Gear cutting is a machining process for creating a gear. The most common gear-cutting processes include hobbing, broaching, milling, and grinding. We produce various types of gears.

Material Brass/Bronze,plastic, Carbon Steel,Alloy Steel, etc.

Modules 1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc

Machining Process Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching,

Gear Shaving, Gear Grinding and Gear Lapping gear rack

Tolerance Control Outer Diameter ±0.005 mm, Length Dimension ±0.05 mm

Heat Treatment Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding……

Teeth Accuracy DIN Class 4, ISO/GB Class 4, AGMA Class 13, JIS Class 0 gear rack

Surface Treatment Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating……