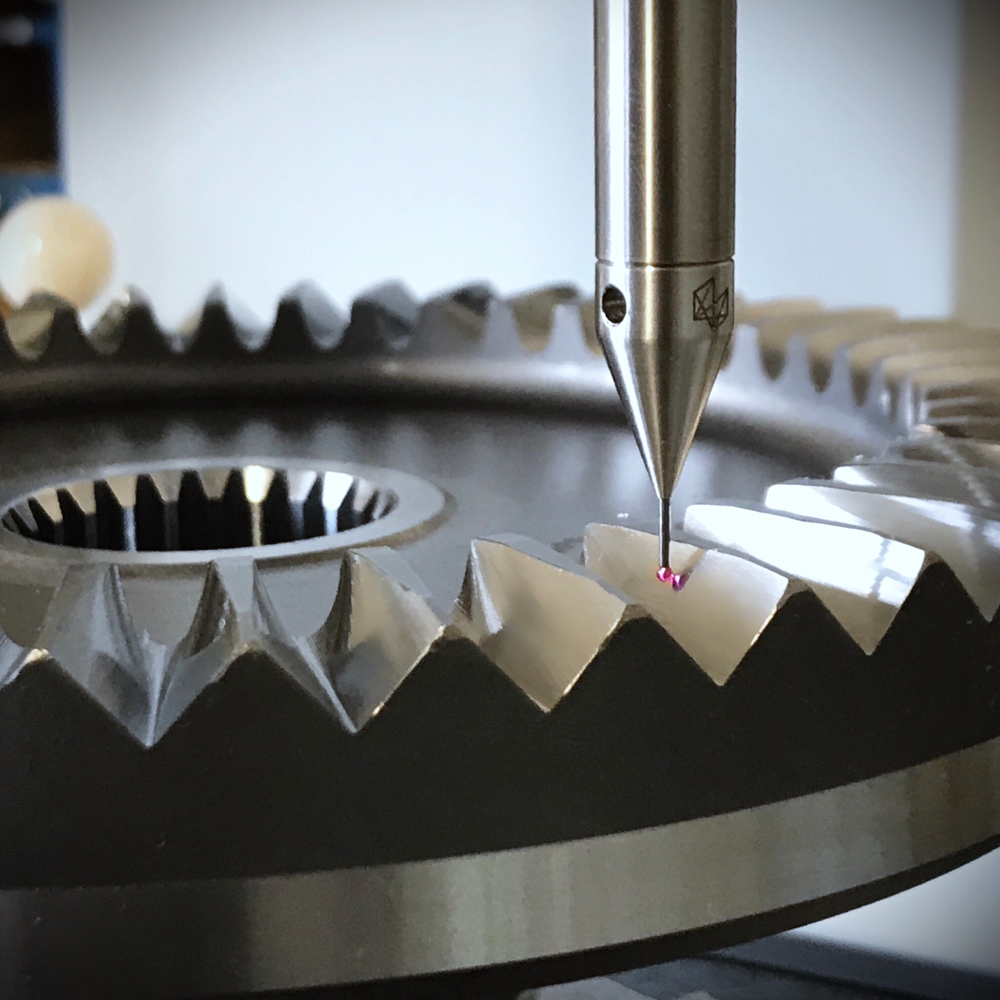

Product Description

ZheJiang CHINAMFG Parts Manufacturing Co., LTD mainly engages in the parts and assembliesof domestic trucks such as Heavy Duty Truck, ZheJiang Automobile, CHINAMFG Xihu (West Lake) Dis., Xihu (West Lake) Dis.fengXihu (West Lake) Dis.n, Ouman, Beiben, Liugi, etc. The company adheres to theprinciples of honesty and trustworthiness, authenticity, quality and quantity assurance, andreputation first to provide comprehensive services to dealers and suppliers across thecountry. Strictly control quality for customers and provide excellent pre-sales and af-ter-sales service.. mainly engages in the parts and assembliesof domestic trucks such as Heavy Duty Truck, ZheJiang Automobile, CHINAMFG Xihu (West Lake) Dis., Xihu (West Lake) Dis.fengXihu (West Lake) Dis.n, Ouman, Beiben,Liugi, etc. The company adheres to theprinciples of honesty and trustworthiness, authenticity, quality and quantity assurance, andreputation first to provide comprehensive services to dealers and suppliers across thecountry. Strictly control quality for customers and provide excellent pre-sales and af-ter-sales service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 3month |

|---|---|

| Warranty: | 3month |

| Certification: | TUV |

| OEM: | Az712732001113 |

| Materials: | 20crmnti |

| Weight: | 28kg |

What are the safety considerations when working with crown gear systems?

Working with crown gear systems requires attention to safety to prevent accidents and ensure the well-being of individuals involved. Here are some important safety considerations when working with crown gear systems:

- Training and Knowledge:

Ensure that individuals working with crown gear systems have received proper training and possess the necessary knowledge and expertise. They should understand the gear system’s operation, potential hazards, safety protocols, and emergency procedures. Adequate training helps minimize the risk of accidents and promotes safe working practices.

- Protective Equipment:

Provide appropriate personal protective equipment (PPE) to individuals working with crown gear systems. This may include safety glasses, gloves, ear protection, and any other necessary equipment based on the specific hazards associated with the system. PPE helps safeguard against potential injuries from flying debris, noise, or contact with moving parts.

- Machine Guarding:

Ensure that crown gear systems are properly guarded to prevent accidental contact with the moving gears. Install protective barriers, covers, or interlocking mechanisms to restrict access to hazardous areas. Machine guarding helps prevent injuries and keeps personnel safe from potential pinch points, entanglement, or crushing hazards.

- Lockout/Tagout Procedures:

Follow lockout/tagout procedures when performing maintenance or repair tasks on crown gear systems. Lockout/tagout involves isolating the equipment from its power source and affixing lockout/tagout devices to prevent unintended energization. This procedure protects workers from the unexpected startup of machinery and ensures their safety during maintenance activities.

- Routine Inspections:

Regularly inspect the crown gear system for any signs of wear, damage, or abnormalities. Look for loose or missing bolts, excessive vibrations, unusual noise, or leaks. Detecting and addressing potential issues through routine inspections helps prevent accidents and maintain the safe functioning of the gear system.

- Proper Lifting and Handling:

When moving or lifting crown gear components, adhere to proper lifting techniques and use appropriate lifting equipment. Crown gears can be heavy, and incorrect lifting or handling can lead to strains, sprains, or dropped objects. Follow ergonomic guidelines and use mechanical aids such as cranes, hoists, or lifting slings to ensure safe lifting practices.

- Emergency Preparedness:

Establish emergency preparedness protocols specific to crown gear systems. This includes clear communication channels, knowledge of emergency shutdown procedures, and access to first aid supplies. Train personnel on how to respond to emergencies, such as gear system malfunctions, injuries, or unexpected incidents.

Promoting a safety-conscious culture, providing ongoing safety training, and ensuring the implementation of appropriate safety measures are critical when working with crown gear systems. It is important to adhere to local safety regulations, follow manufacturer guidelines, and prioritize the well-being of individuals involved in operating, maintaining, or repairing crown gear systems.

Can you explain the process of gear engagement involving crown gears?

The process of gear engagement involving crown gears follows a specific sequence to ensure proper meshing and efficient power transmission. Let’s explore the steps involved in the gear engagement process with crown gears:

- Approach:

During the gear engagement process, the gear teeth of the mating gears approach each other. As the crown gear and the mating gear come closer, the teeth start to interact and prepare for engagement.

- Tooth Contact:

Once the teeth of the crown gear and the mating gear make contact, they begin to mesh together. The curved tooth profiles of crown gears allow for gradual contact between the teeth, reducing impact forces and ensuring smoother engagement.

- Alignment:

As the tooth contact progresses, the crown gear and the mating gear align themselves to achieve proper meshing. The teeth of the crown gear and the mating gear should align accurately to ensure optimal power transmission and minimize noise and wear. Proper alignment also helps distribute the load evenly across the gear teeth.

- Meshing:

Once the teeth are in contact and properly aligned, the crown gear and the mating gear mesh together. The teeth of the crown gear fit into the spaces between the teeth of the mating gear, creating a mechanical interlock. This meshing allows for the transfer of torque and rotation between the gears.

- Power Transmission:

With the gears meshed, power transmission occurs as the torque from the driving gear (such as a motor) is transferred to the driven gear through the crown gear. The crown gear, with its larger contact area and perpendicular tooth orientation, facilitates efficient torque transfer and power distribution within the gear system.

- Disengagement:

When the engagement process is complete or when the power transmission needs to be stopped, the gears disengage. The disengagement process involves the reverse sequence of the engagement steps. The teeth gradually separate, and the gears move away from each other, ceasing the meshing and interrupting the power transmission.

The gear engagement process involving crown gears is crucial for ensuring smooth and efficient power transmission. Proper alignment, gradual tooth contact, accurate meshing, and reliable disengagement are essential for minimizing wear, reducing noise, and maximizing the overall performance and longevity of the gear system.

What is the purpose of using a crown gear in machinery?

A crown gear, also known as a contrate gear or a contrate wheel, serves several important purposes in machinery. Let’s explore the key purposes and advantages of using a crown gear:

- Directional Change:

One of the primary purposes of a crown gear is to change the direction of rotation in a mechanical system. By meshing a crown gear with other gears, the rotational motion can be redirected by 90 degrees. This directional change capability is particularly useful in applications where a change in motion direction is required, such as conveyors, cranes, and other machinery.

- Force Distribution:

Crown gears are also used to distribute forces and torques in machinery. By meshing a crown gear with other gears, the load can be spread across a larger contact area. This distribution of forces helps reduce stress and wear on individual gear teeth, promoting smoother operation and improved durability of the gear system.

- Steering Mechanisms:

Crown gears find significant application in steering mechanisms, especially in automotive systems. They are commonly used in rack and pinion setups, where the crown gear meshes with a rack (a linear toothed component) to convert rotational motion into linear motion. This arrangement enables precise control and smooth movement in steering systems, ensuring reliable and accurate vehicle maneuvering.

- Motion Control Systems:

Crown gears play a crucial role in motion control systems, particularly in automation and robotics. They allow for changes in motion direction, force distribution, and precise control of movement. By utilizing crown gears, robotic arms, gantry systems, and other automated equipment can achieve complex and accurate motions essential for various industrial processes.

- Compatibility with Different Gear Types:

Crown gears have the advantage of being compatible with gears that have parallel axes or bevel gears with intersecting axes. This versatility allows them to mesh smoothly with different gear configurations, enabling torque and rotational motion transfer between various components in a machinery setup.

- Application-Specific Uses:

The specific purposes of using a crown gear in machinery ultimately depend on the application requirements. Crown gears can be customized and integrated into machinery to fulfill specific needs, such as changing motion direction, distributing forces, enabling precise control, and ensuring compatibility with other gear systems.

In summary, the purpose of using a crown gear in machinery includes directional change, force distribution, steering mechanisms, motion control systems, compatibility with different gear types, and application-specific uses. Crown gears offer unique advantages that contribute to the smooth operation, durability, and efficiency of machinery in various industries.

editor by CX 2024-04-15